水色澄 如一輪皎潔的明月

從茶色就顯示祛濁取淨的道地功夫 優雅地讓目光舒適起來

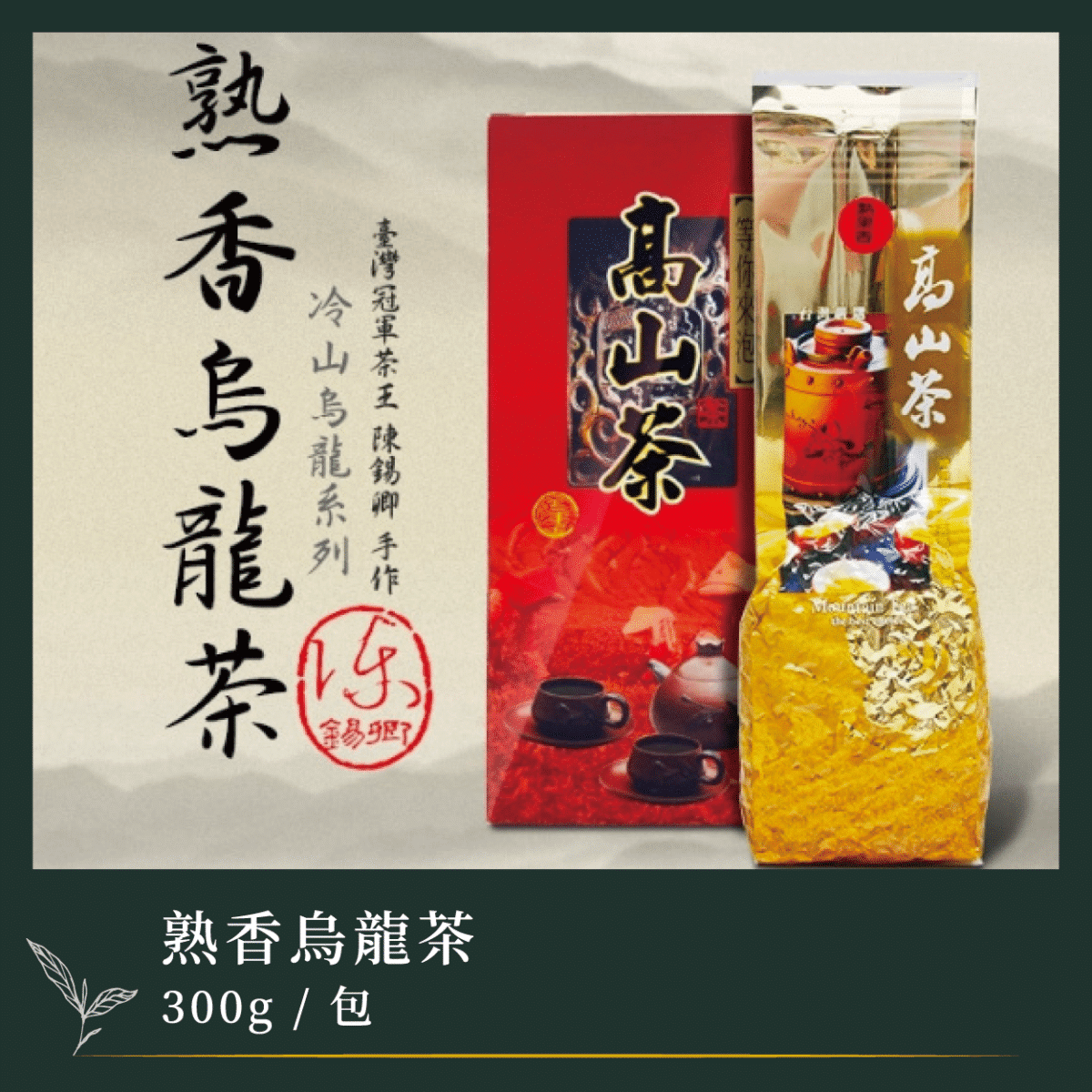

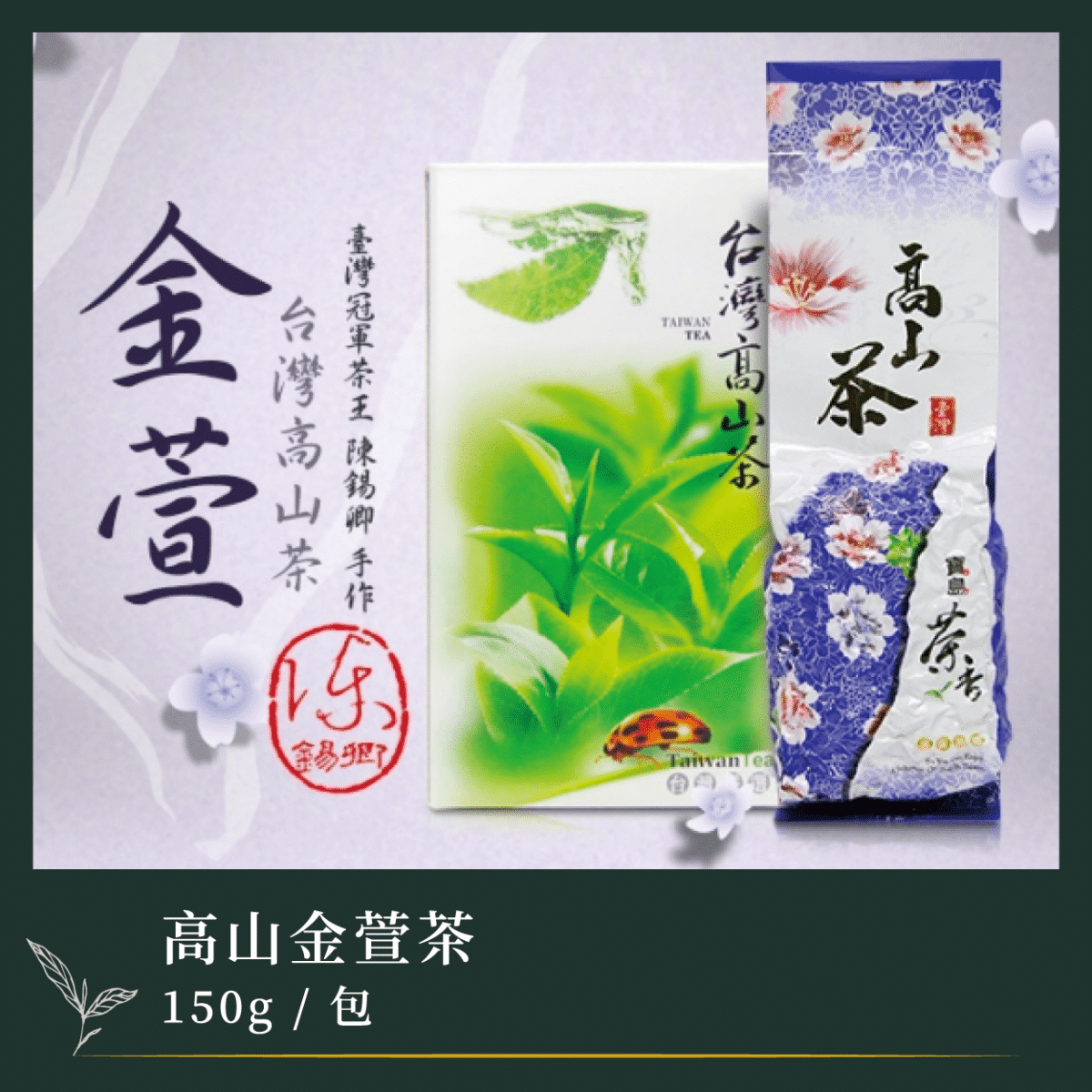

穩香 來自層層的把關

允芳茶園對於製茶的過程更要求精準 讓茶除了回甘 更回香

讓國際看見台灣世界級的好茶

允芳茶園 以好山好水的台東茶 飄香於世界

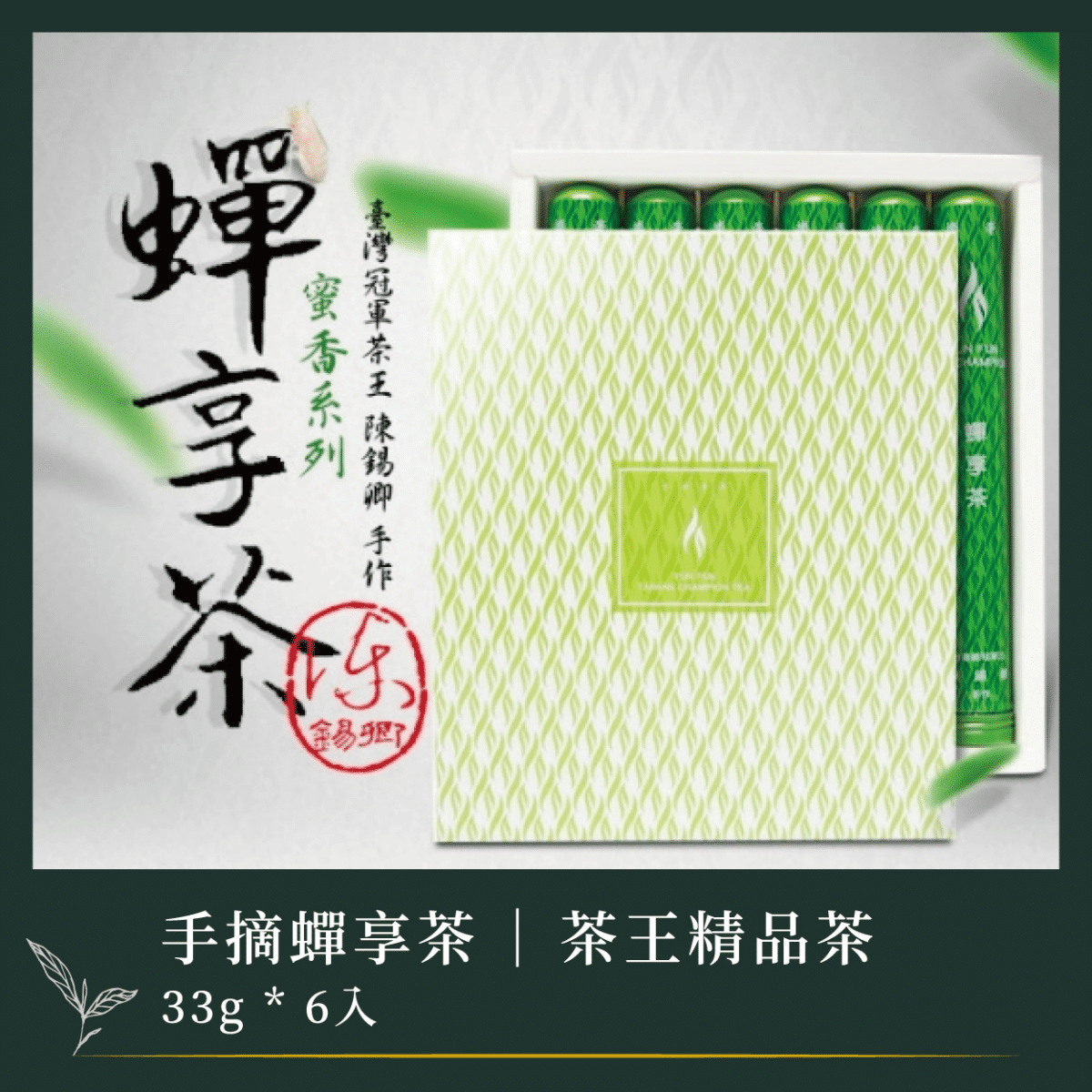

手摘奢華

台灣茶總冠軍 陳錫卿 手作

Previous

Next

允芳茶行

允芳茶園,以好山好水的台東茶,飄香於世界!

允芳茶園的努力,讓人從此對好茶版圖改觀,因為台東的優良地理氣候條件, 也能種出讓令人激賞的頂級好茶!

台灣茶王 -

種茶人陳錫卿 種出茶王美名

品到好茶不難,種出好茶卻是一門深奧的學問。台東茶農陳錫卿二十年來奪下四十多次特等茶獎,更拍賣出一斤八十八萬元的天價茶葉,博得「台灣茶王」美名。

好茶來自茶農的細心呵護、栽培。以精緻農業聞名的台灣,素以好茶聞名。近幾年,台東一位種茶二十餘年、拿下四十多次特等獎獎項及台灣十大傑出農民獎,有「茶王」之稱,他的名字是,陳錫卿。

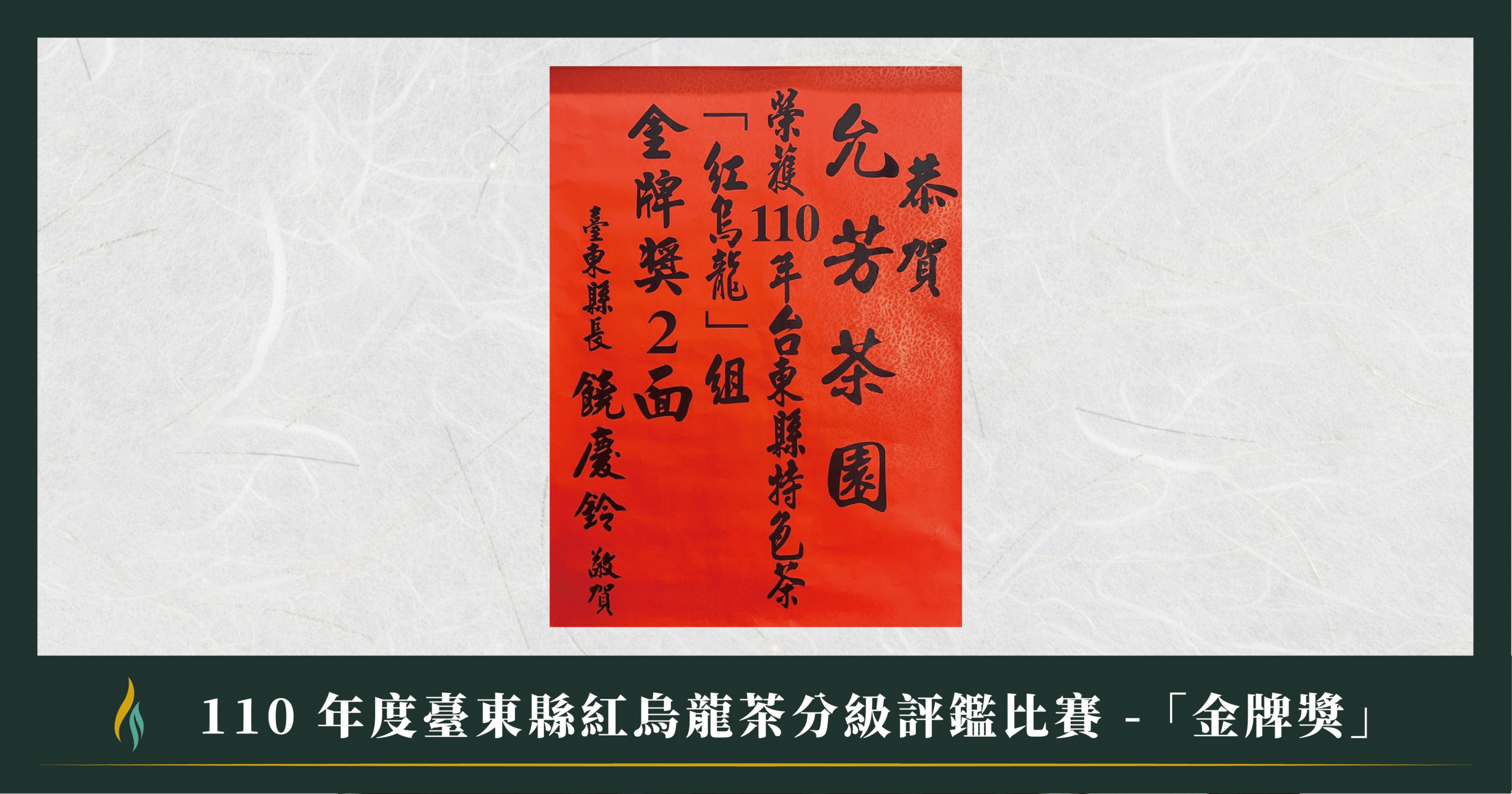

初見陳錫卿,樸素外表平凡無奇,口音略帶著台灣國語,態度隨和親切,第一眼,很難聯想眼前這個人就是連拿二十多屆冠軍的茶王;但牆上掛的冠軍茶匾額及店內四處可見的冠軍獎項匾額,不意點明眼前這位,擁有一身種好茶的本領。

從小在茶園中長大,但陳錫卿從沒想過自己會與種茶為伍。退伍後,他回台東探視父母,當時父母年歲已大,茶園弄得稀稀落落,好不容易盼到兒子退伍,便要求他回鄉幫忙,陳錫卿因而意外地踏進了茶園,成了專職的茶農。

種茶人陳錫卿 種出茶王美名 <文字摘錄今周刊 >